PC Cooling – The Technical Shit that Overclockers Should Know, But Don’t!

I’m going to start this off with a disclaimer:

Disclaimer: This shit is a dumbed-down version of the very technical, which makes it a very long article. It is meant to help you understand the fundamentals of PC cooling. It is NOT a guide to building a cool PC!

There! Now that that’s out of the way, let’s get down to business. PC Cooling is one of the core competencies that every PC gamer or PC enthusiast need to understand. Why? Well most boneheads out there throw thousands of $$$ at prime PC hardware, but don’t really understand what is happening when it comes to cooling. Rather than take the time to plan-out their gaming rig, they instead pack it full of components that they think will help keep it cool when they overclock, then wonder why the fucking fuck their rig is still getting hot! Turns-out old Taco Supreme Being here has had extensive experience with this. And I’m here to help and not just reference my pseudo-name in the third person. When I worked as an engineer for a motherboard manufacturer (that shall remain unnamed here), I not only engineered motherboards for computers, but also cooling solutions for chipsets and CPUs. So all you smug motherfuckers out there that think you’re cool because you built a water-cooled system, think again. Chances are you fucked it up and don’t even know (and are getting by on the sheer properties of water cooling itself). Odds are 10 to 1 that I can build a air-cooled system that performs better than your water cooled system any day! But really, I’m not here to belittle you, I’m here to bring you to the next level! I want you to have that water cooled system, and understand how to make it perform way better than it was designed to.

So let’s start with the basic terms that we use when talking about PC Cooling. This list below is basic, but also very relevant. These terms are in alphabetical order, so familiarize yourself with them so reading the rest of this article becomes a bit easier:

Ambient: Room temperature. Or, the idle temperature within a defined space. (we’ll refer to ambient room temperature and ambient case temperature)

Celsius (Centigrade): Temperature scale referenced to absolute zero. Pure water freezes at 0°C and boils at 100°C (at one atmosphere of pressure).

Conduction: Heat transfer through a solid material.

Conduction Coefficient: Measure of how efficiently a solid conducts heat.

Convection: Heat transfer from a solid into a liquid or gas.

Convection Coefficient: A measure of how efficiently a fluid (liquid or gas) transfers heat to or from a solid.

Differential Temperature: The difference between two temperatures.

Energy: Units of force multiplied by distance.

Interface: The point where two different solids meet.

Lapping: A process used to improve the surface finish of a heat sink.

Power: A measure of how quickly work is performed. Work divided by time equals power.

Specific heat: The thermal energy storage capacity for a material.

Transient: A condition marked by change.

Okay! Now for a few acronyms and phrases. The following list of acronyms and phrases are commonplace when it comes to PC cooling. However, they are often misinterpreted and misused. So be sure to get them right so you don’t sound like a fucking idiot when you go to Monkey Center to buy your cooling shit!

HSF: Heat Sink and Fan

TIM: Thermal Interface Material

IHS: Integrated Heat Spreader

Die: The small rectangular block at the center of a CPU package that contains all the integrated circuits, transistors, and shit that make-up the core of the CPU

De-lidding: The process of removing the IHS from the Die of a CPU.

Radiator: A collection of tubes (usually copper) with fins attached for the purpose of aiding the conduction and convection of heat away from the fluid that flows through them.

Reservoir: A container that holds an amount of liquid.

Pump: A device that moves liquid from point A to point B.

Water Block: A heat sink designed specifically to use a liquid for convection.

AIO: All-in-One. Here referred to an All-in-One cooler which is a closed-system, pre-manufactured water cooling solution that is made-up of a Radiator, Heat Sink, Pump, and Cooling Fans.

Thrice: Shakespearean for “three times.” But really just an English form of a word that nobody really uses anymore except me. Maybe Edgar Allen Poe too… but he was too dark for me to quote from. Hmmm… Shakespeare was dark too, but he was eloquently and whimsically dark. He didn’t spin grim tales of hearts beating in the floorboards of a house. I had nightmares about “The Tell-Tale Heart” as a child. I wonder if I could send my therapy bills to the Edgar Allen Poe foundation? …

Finally to the meat of this article! Let start by trying to understand conduction. For us we are concerned with conduction in three primary areas: the transfer of heat from the CPU die to the IHS, the transfer of heat from the IHS to the heat sink, and transfer of heat through the heat sink to the place where it is removed by convection. In a perfect world, every CPU die would be mated directly to the HSF and not have a need for a TIM. We’ll touch more on that idealism later, but for now:

In many generations of CPUs, the manufacturer did not include an IHS, so in order to make sure that heat was transferred efficiently from the die to the heat sink, some brainiac came-up with the concept of a TIM. TIMs have been around more than 6 decades and have both pros and cons. The pros of TIMs are essentially that they fill in the flaws of heat sinks that were manufactured poorly or cheaply, and they allow for some tolerance when heat sinks are installed by amateurs (not much, but some).

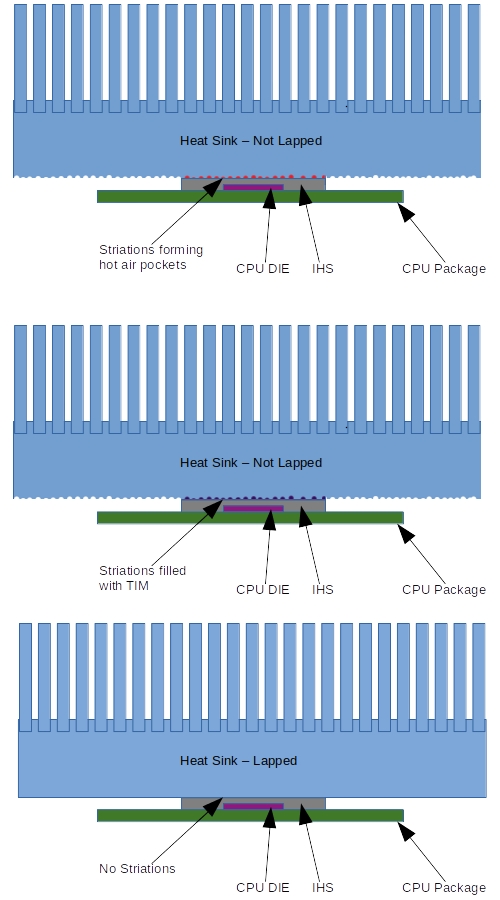

To illustrate this, think of an aluminum heat sink that was produced through the process of extrusion. Extrusion is where you heat a substance to a malleable state and force it through an opening with a specific shape. This process however tends to create striations (tiny grooves) on the surface of the heat sink that is intended to mate with the die of the CPU. Why is this bad Taco? Let me ‘splain Lucy! When mated to the CPU die, those little striations create air pockets between the die and the heat sink. When there is no air flow, those air pockets insulate the CPU rather than allow for heat to be conducted away. Heat transfer is proportional to the temperature difference on an object. If the temperature differential doubles, the heat transferred doubles. Also, the conduction coefficient is proportional to heat transfer. If the conduction coefficient doubles, the heat transfer doubles.

So where do striations come into play here? Well, since those little grooves create little insulating pockets of air, the temperature differential between the heat sink and the die remain relatively isolated therefore the conduction coefficient between the two is decreased because the two remain relatively separate.

Enter the TIM. A TIM’s sole purpose is to fill-in those little air pockets and increase the conduction coefficient between the die and the heat sink. This however brings us to the cons of the TIM. While TIMs are usually far more conductive of heat than air, they are usually less conductive of heat than the heat sink. Probably the biggest con of a TIM is that it is regularly misused. By misused, I mean folks (not you of course) generally apply too much. As I just noted, a TIM conducts heat better than air, so removing those little air pockets is good, but when you use too much, it also becomes an insulator and can decrease the conduction coefficient between the die and the heat sink. Many people wrongly think that TIMs (Thermal Paste, Thermal Compound, Thermal Grease, etc…) are really, really good for PC cooling, so they apply way too much hoping that it will help keep the CPU cool. Ideally however, You’d have no air pockets and as little TIM between the die and the heat sink as possible. Enter “lapping.”

As defined earlier, lapping is not a form of foreplay you do with your partner, rather it is the process of using a super fine sandpaper to remove those little striations on the surface of the heat sink that mates to the die of the CPU. I won’t get in to how to lap your heat sink, but in the last stage of lapping usually involves a polishing compound that puts a mirror finish on the heat sink. What this does is increases contact between the die and heat sink directly thus increasing the conduction coefficient. In other words, it increases the efficiency of heat transfer from the die to the heat sink by removing more insulating materials like air and TIMs. With proper lapping, you can drop the temperature of your CPU by 1-2 degrees C! (insert pretty picture below – it’s the only one for now)

I suppose this is a good time to talk about which metals are the best conductors of heat. The two most common materials used in heat sink construction are aluminum and copper. Some smart guys and girls at sometime in our history did some tests on heat conductivity of some metals and came up with some results. I’m already pages in to this, so I’ll spare you the details (which you can google for yourself). Out of the two mentioned, copper is more conductive than aluminum. Are there other materials more conductive than copper? Yes, but they are generally not economically viable to use because they are too expensive. for example, silver and diamonds conduct heat better than copper or aluminum, but who has the scratch to buy a silver heat sink? Considering price for performance though, copper is usually the way to go.

Alrighty then. Let’s talk convection. Convection happens once in air-cooled systems and thrice in water cooled systems. Remember our definition of convection (and thrice)? Convection is when heat is transferred to a gas or liquid. In an air-cooled system, heat is transferred directly to the air inside the PC case via the heat sink.

Let’s stay focused on air-cooled systems for a bit. Removing heat from the heat sink using air can be a bit tricky at times. Ever come across one of those systems that sounds louder than an F-16 and ask yourself why you need such horrifically loud and fast fans? The reason is simple. In these cases, the heat sink is usually small, with insufficient amounts of fins. You’ll usually find these small heat sinks in small spaces where there’s not room for a big-ass, motherfucking heat sink. Since air has a limited specific heat (remember the terms above), a larger volume of air is needed to store more heat. Fortunately for us, air is a gas and can be easily manipulated with fans. We use fans to force more air into contact with the heat sink this effectively increases the volume of air and thus increases the convection coefficient.

HOWEVER, this creates a problem with the ambient temperature inside the case. Remember that air has a specific heat. If all the air inside the case has reached it’s specific heat capacity, then the fastest fans in the world won’t help. you’ll just be moving hot air around and creating more heat. This is BAD in the PC world. Bad because when PCs get hot, performance drops and sometimes, even the specific heat of an IHS or heat sink is reached. When this happens, you may as well go get some butter to go with that toasted CPU (and to most likely use as lube for your hand because that’ll be all you can do until you replace the toasted CPU). How do we avoid toasted CPUs and buttered genitalia? We add intake and exhaust fans to our case to bring in nice, cool, fresh air, and expel that nasty hot air. Doing this will lower the ambient temperature in the case and increase the convection coefficient by supplying air that has not reached it’s specific heat capacity.

Keeping that in mind, the other popular way to increase the convection coefficient is to increase the surface area of the heat sink itself. Why does this help? This helps because it increases the volume of air that comes in contact with the heat sink. This is why you see large heat sinks with an obscene amount of fins. Oddly enough, those striations we were talking about earlier being a bad thing between the die and heat sink, are now a good thing because they effectively increase the surface area of the heat sink’s fins allowing more air to come in direct contact thus increasing the convection coefficient.

Let’s pause here for a moment to remember some 5th grade science. If you haven’t made it to the 5th grade yet, don’t worry, this info is pretty basic and will help you plan the air flow of your PC. What is this mad science I’m asking you to recall? Well, I want you to recall that hot air rises and cool air sinks. Heat stored as energy in air excites air particles and causes them to push apart and expand. This expanding hot air is less dense than cold air so it rises. The more dense cold air sinks to the bottom. I’m sure that a density-gravity correlation has some play here, but I’m already dense and grave enough as it is, so we’ll skip that bit. But, following this logic, it makes sense to place your intake fans for your PC lower (relative to the room it’s in), and the exhaust fans higher. This plays on ambient room temperature as well. The ambient temperature of the lower-half of a room should be cooler than the top half. I’ll let you figure-out where I was going with that… I want to move on to water-cooled systems.

The principles in water-cooled PCs are relatively the same as in air-cooled ones. The only difference is the materials used to remove heat. In a water-cooled system, conduction happens twice and convection happens thrice: conduction of heat from die to water block, convection of heat from water block to liquid, convection of heat from liquid to radiator tubes, conduction of heat from radiator tubes to radiator fins, convection of heat from radiator fins to air.

Sound complicated? It is! a lot can go wrong with a water-cooled system, joints can fail and leak coolant in to your PC, the pump can fail, you can get an algae or sludge buildup that (aside from being gross) acts as an insulator, etc… So when so much can go wrong, why the fuck would we even entertain a water-cooled system? Well, as complex as it sounds, it boils down to one basic principle: The temperature differential between each end of the cooling system is inherently greater than that of an air-cooled system and allows for greater conduction and convection coefficients in the system itself which increase it’s capacity and efficiency for removing heat.

“Holy fuck Taco! That’s a lot of info! But how is this possible? Why is a water-cooled PC better?” Oh my dearest, cutest, naivest reader… this is possible simply because liquids have a higher specific heat that gasses. There is a much higher convection coefficient when transferring heat from a solid to a liquid than when transferring heat from a solid to a gas. If you have a large volume of liquid coming in contact with the water block, you can remove more heat. This is where the term reservoir becomes important. Why add a reservoir to your system? Well, adding a reservoir allows you to increase the volume of liquid in the system allowing for an even higher convection coefficient. But even with all this liquid, we still need to remove the heat from the system, which brings us to the radiator.

A radiator is essentially a heat sink for liquids. All those copper tubes running through the radiator are soldered to fins that have a large amount surface area for air to make contact. Usually, radiators are large in order accommodate a plethora of fins. The reason why they can be so large is that they are usually connected remotely by tubes allowing you to place the radiator far, far away from the crowded inner-space of your PC. You employ the services of an underpaid, underappreciated water pump to move all that liquid through the radiator. Now the same principles apply as with any heat sink; more surface area, more air contact, more heat removed from the system. But now that we have a ginormous amount of surface area to work with, we don’t need jet-speed fans to have sufficient air contact with the heat sink (radiator). Generally bunches of copper tubes equals a greater convection coefficient for heat transfer from liquid to solid. The solid here being the mass that make-up the radiator. Usually this total mass is greater than that of a standard heat sink, so it has a greater conduction coefficient. Since it’s mass is greater, you can attach more surface area fins allowing for a greater convection coefficient for heat transfer from the solid (radiator) to gas (air). All this allows for a greater temperature differential from point A (the die) to point B (the air) which means you can remove heat quicker and more efficiently than with just a standard old, pansy-assed heat sink!

“So Taco, I should just go get an AIO cooler right?” My befuddled friend, AIOs are an option, but let’s take a logical approach to the concept. AIOs have a radiator, cooling fan(s), water block and pump. They use liquid to move heat from the die to the radiator. True that for all intents and purposes, AIOs are water coolers. But are they good? IMHO, not really. While they usually do offer a slightly quieter solution to standard HSFs, they combine the pump with the water block and have a limited volume of liquid in the closed system. Also, manufacturers playing on the hype are mass-producing the liquid-filled cooling solutions with marginal quality control. In the past year, I have seen no less than 10 AIOs that leaked, exploded, or otherwise plain failed, resulting in damage to the motherboard, processor, RAM, SSD, and power supply. Also, AIOs are usually designed to fit in smaller spaces, so they have smaller radiators. The benefit of a few degrees C over a well designed HSF is not worth the risk! If you want a quiet water cooled system. take the time to build it yourself. Then you have control over the quality AND performance of the system. Don’t get me wrong here. AIOs are not evil or anything, I just think they are a half-assed offering as a water cooler. Take for instance making the pump part of the water block. A pump is a motor which uses electricity and produces the thing called heat. When you place the pump on the water block, the liquid now has to remove not only the heat from the CPU, it has to remove the heat from the pump. Generally this is an inconsequential amount of heat, but it is heat nonetheless. To me this is as idiotic as heat sinks you see on graphics cards where the fan sits inside the fins of the heat sink directly atop the GPU. Not only have you reduced the surface area of the heat sink by removing fins, you’ve sandwiched an inadequate piece of aluminum between two heat sources…

Maybe one day here soon, I’ll get ambitious and build another water cooled system, take pictures, and do a step-by-step guide, but the divorce left me poor (for now), so that’ll have to wait. I hope you found this info helpful!

I didn’t believe that lapping would drop the temperature that much. I watched a few how-to’s on youtube then lapped away at my heatsink. I couldn’t believe it when I re-ran AIDA64 benchmarks and saw that my average CPU temp was almost 2 deg C cooler than before I lapped it! I’m going to redo my entire rig based on what I’ve learned here! Thanks for the post!

i7-9700K

Asus ROG Strix RTX 2070

32GB DDR4 3200

Samsung EVO 970 512GB NVME